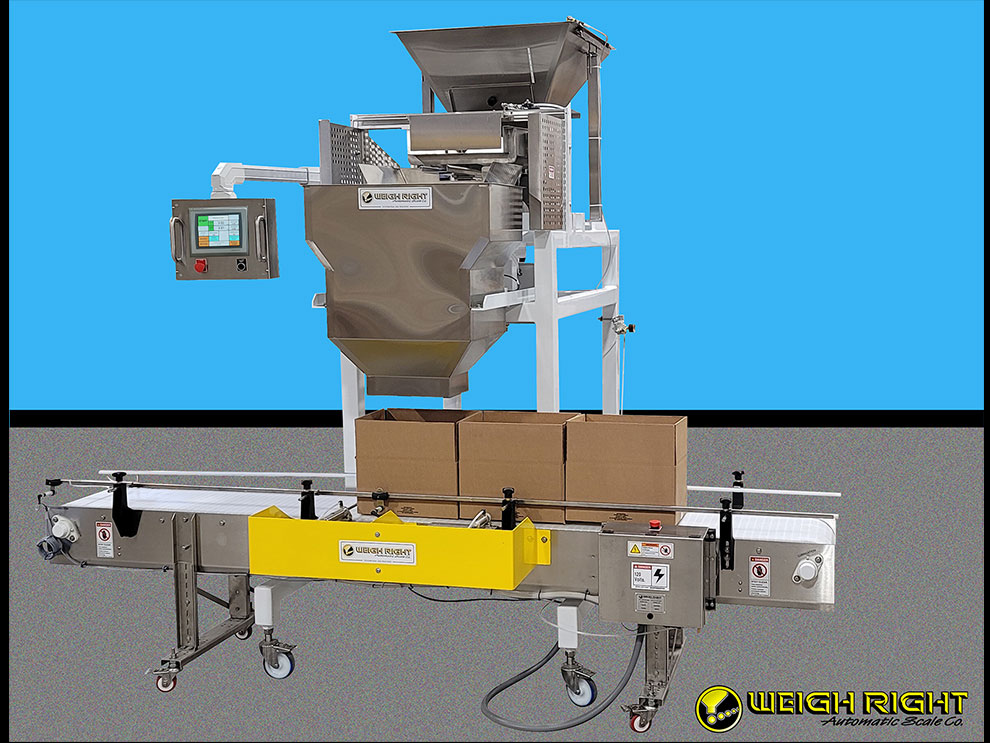

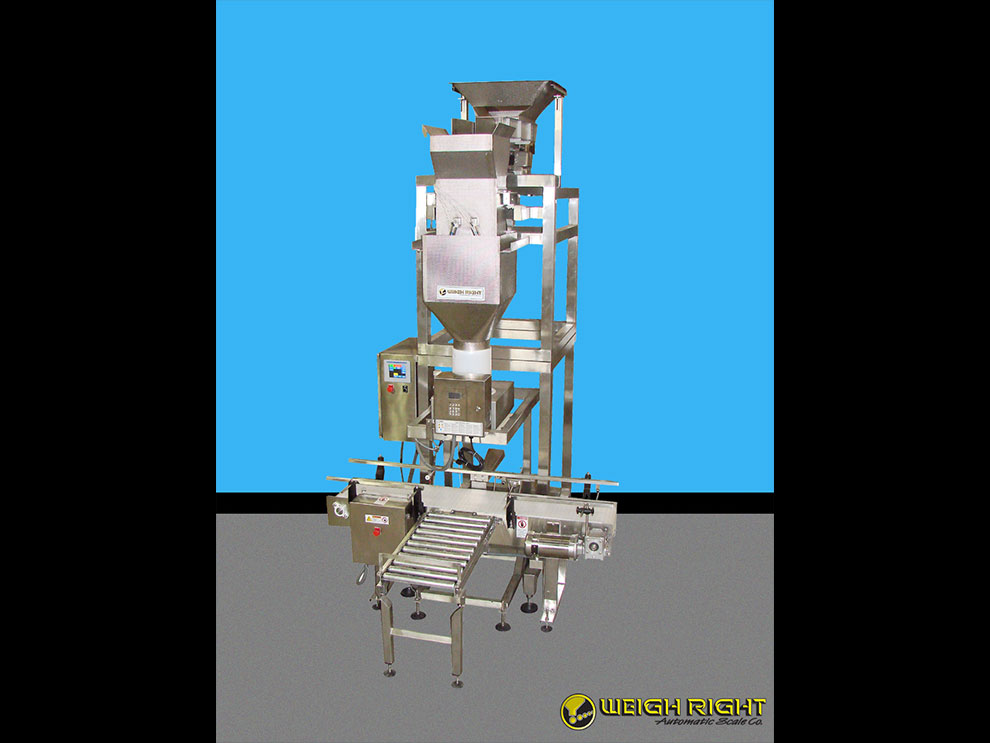

Fully Automatic Direct Fill Gross Weigher

The G-50 automated models come with a power roller conveyor that provides complete control of case indexing with individual zones that start and stop the case as needed.

When activated, the rollers move the case into position under the filling section where it gets automatically tared which is quickly followed by the vibratory feeder filling product into the case. The vibratory feeder will fill at a fast rate to reach the target weight quickly and then slowly come to a stop after accurately completing the desired package weight.

NOTE: The number of vibratory trays needed to move the product accurately into the weigh bucket is determined by the product’s flow characteristics. Each system is designed to handle as many of your products as possible.

The G-50 comes available in non-washdown and all stainless steel washdown models, see the photos below in our Image Viewer.

Your G-50 Direct Fill Scale Options:

- Customize conveyor for different lengths.

- Multi-directional movement of cases

- Case vibration after the fill (pneumatic or square roller conveyor)

- Incorporate a metal detector under the feeders prior to product filling into the case.

- Allen Bradley Controls

- And more…

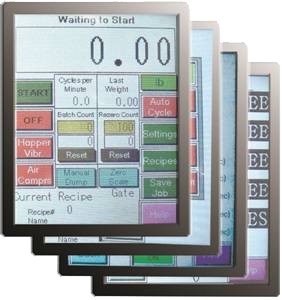

Our scales come standard with touch screen menu driven controls offering job storage, help menus and easy to read graphics. All scales come with non-proprietary components.

MENU DRIVEN CONTROL INTERFACE:

- 50 Job Memory Storage

- Auto Zero

- Weight Options: lbs., grams, kg, or ounces

- Count Mode (count by weight)

- Batch Count

- Help Menu Per Screen

Return to: G-50 Direct Fill Main Page

Weights & Rates*

*Rates are estimated. Final results determined bu product density and flow characteristics. We invite you to send us your product samples for free testing and results.